November 26, 2025

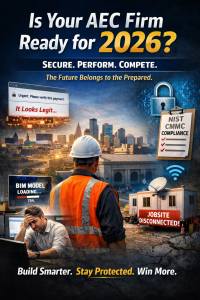

The Tech Crisis KC AEC Firms Can’t Ignore in 2026

Here is the plain truth: after decades moving between drafting rooms, job trailers, and server closets, I have never seen pressure building the way it is right now for Kansas City AEC firms.

Most folks think the main challenges are supply chain, labor shortages, or inflation. But the real threat is quieter. It shows up as delays, blown budgets, and leaders losing sleep without knowing why.

That threat is technology friction.

Not lack of technology.

Not reluctance to adopt it.

But the daily drag caused by systems that do not talk, field tools that fail when they should not, and compliance rules that grow stricter every quarter.

In KC, this friction is getting amplified by massive models, regional collaboration, and federal project requirements. Firms are stretched between bigger workloads and higher expectations. And the ones who do not get in front of it will lose time and opportunity faster than they realize.

Why 2026 Will Push AEC Firms Harder Than 2025

Kansas City is busy. Data center projects near KCI are pulling in engineering and utilities work. Industrial absorption keeps climbing. Architectural and civil firms are tackling steady downtown and suburban activity.

More work is good until your tech stack becomes the bottleneck.

Here is what is shifting beneath the surface.

1. BIM Files Keep Getting Bigger

Ten gigabyte models are common now. Add LiDAR scans and point clouds, and networks buckle. If your workstation, storage, and cloud systems are not tuned together, you lose time every day.

2. Multi Firm Collaboration Is the New Normal

KC’s 1,200 plus AEC firms work across shared models, shared platforms, and mixed networks. Every link adds risk and lag. Every delay slows someone’s deadline.

3. Cyber and Compliance Pressure Is Rising Fast

More KC firms are bidding federal, municipal, and utility contracts. CMMC and NIST 800 171 requirements are no longer optional. Leadership feels the weight of staying eligible.

4. Field Teams Rely on Real Time Connectivity

RFIs, submittals, inspections, drones, tablets, and mobile plans all demand instant access. One trailer outage or bad access point can stall a project for hours.

5. Performance Is Now a Business Metric

AEC leaders care about results, not ticket counts.

They ask questions like:

How long does the model take to open?

How stable is Procore?

Are field devices syncing?

Are our backups proven?

These metrics matter more than ever.

The firms that treat IT as infrastructure rather than an afterthought will run faster, bid stronger, and sleep better.

Why Leaders Are Quietly Worried

After talking with principals, PMs, and field supervisors across the KC metro, similar concerns surface again and again.

Fear of schedule slip

They worry a slow model, corrupted file, or lost connection could push deadlines, hurt relationships, or cost a client.

Fear of losing federal work

CMMC and NIST requirements feel confusing. Leaders do not want to risk losing a bid because something in their environment is not compliant.

Fear of embarrassing outages

Nothing feels worse than explaining to a GC why the trailer is offline or a model broke during coordination.

Fear of becoming the bottleneck

Even tech savvy AEC leaders carry quiet anxiety.

They think:

I know enough to be dangerous, but not enough to see every risk.

These firms want confidence, not more complexity. They want systems that feel fast and reliable. And they want a partner who understands Autodesk, Bluebeam, Procore, Civil 3D, and jobsite realities.

The Problem Is Not the Tools. It Is the Drag.

A recent company performed a one hour tech audit. The owner discovered redundant tools, multiple systems doing the same work, and people manually copying info between apps. The total loss:

7,488 wasted hours and $262,080 a year in productivity leakage.

Most AEC firms have the same hidden waste, but multiplied by bigger files, heavier field needs, and stricter documentation.

This is how friction steals billable hours and erodes schedules.

The Real Threat: Delays So Small You Miss Them

AEC firms rarely suffer one catastrophic outage. What hurts the most are the repeated micro failures:

• A model that takes minutes to open

• An Autodesk sync that fails near the end of the day

• Field photos that do not upload until tomorrow

• A plotter that jams right before a submittal

• A plugin that breaks after an update

• A trailer offline during an inspection

Individually, each issue is annoying.

Together, they are devastating.

This is the slow bleed leaders never see coming.

The Firms That Win in 2026 Will Fix Their Friction Now

The strongest KC firms are already taking targeted steps like these:

1. Tuning BIM performance from the workstation to the cloud

GPU ready machines, NVMe scratch drives, optimized Autodesk connections, model cache servers, and stable print workflows.

2. Treating jobsite connectivity like a utility

Trailer kits that deploy fast, with LTE or 5G failover, remote monitoring, and managed tablets.

3. Locking in practical cybersecurity and compliance

Right sized NIST 800 171 and CMMC readiness, with documentation, logs, and evidence collected automatically.

4. Removing duplicate software and hidden costs

Many firms discover thousands wasted every year on unused tools or overlapping subscriptions. Some find enough savings for a full family vacation.

5. Measuring what actually matters

Model open times, RFI cycle time, trailer uptime, file sync reliability, and print queue stability. Not ticket count.

These changes reduce stress, protect schedules, and give leaders back control.

KC Firms That Act Now Will Lead the Region

Kansas City is in a strong building cycle, and the AEC firms with tuned performance, strong security, and steady field support will be the ones dominating the next wave of work.

If this feels familiar, that is a good sign. It means you are aware of the friction and ready to deal with it. You are not behind. You are at the moment where KC leaders decide whether to keep fighting daily tech slowdowns or finally eliminate them.

Your team deserves smoother days.

Your projects deserve fewer surprises.

And you deserve peace of mind knowing the jobsite, the models, and the compliance requirements are under control.